The demand for cannabis products has surged in recent years, leading to increased scrutiny and regulation in the industry. One key aspect of maintaining compliance and ensuring product quality is the removal of THC (tetrahydrocannabinol), the psychoactive component of cannabis.

For manufacturers aiming to produce THC-free products, whether for medicinal, recreational, or industrial purposes, the right equipment is crucial. This article delves into the effective equipment to remove THC, ensuring that your products meet legal standards and consumer expectations.

Understanding the Need for THC Removal

The cannabis industry encompasses a wide range of products, from oils and edibles to topicals and beverages. While THC is a desirable component in many recreational products, it must be minimized or eliminated in others, particularly in markets where THC-free claims are essential. These products include those targeted at patients who seek the therapeutic benefits of cannabinoids without the psychoactive effects, as well as products intended for regions with strict THC regulations.

Chromatography: The Gold Standard for THC Removal

One of the most effective methods for removing THC from cannabis extracts is chromatography. Chromatography is a separation technique that exploits the differences in the chemical properties of compounds to isolate specific components. High-performance liquid chromatography (HPLC) and supercritical fluid chromatography (SFC) are two prevalent types used in the cannabis industry.

HPLC (High-Performance Liquid Chromatography):

HPLC involves passing a liquid sample through a column packed with a stationary phase. The different compounds in the sample interact with the stationary phase to varying degrees, causing them to elute at different times. By carefully selecting the stationary phase and operating conditions, THC can be effectively separated from other cannabinoids and impurities.

SFC (Supercritical Fluid Chromatography):

SFC uses supercritical fluids, typically carbon dioxide, as the mobile phase. This method offers several advantages, including faster run times and reduced solvent use compared to traditional HPLC. SFC is particularly effective for large-scale THC removal operations, providing both efficiency and scalability.

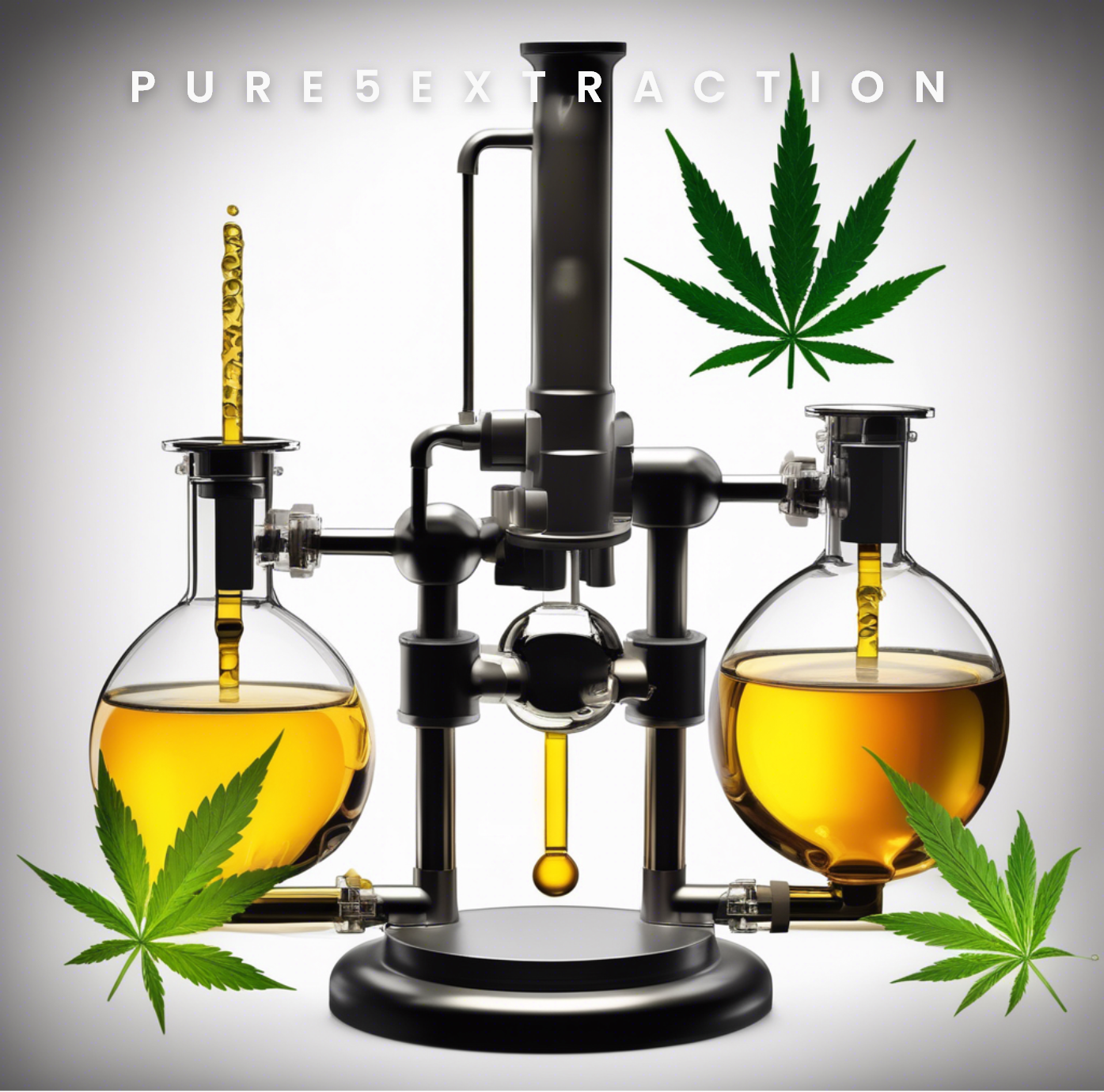

Distillation: Purifying Cannabinoid Extracts

Distillation is another widely used technique in the cannabis industry for THC removal. Distillation involves heating a liquid to create vapor and then cooling the vapor to collect the purified component. There are two main types of distillation used for cannabinoid purification:

Short Path Distillation:

Short path distillation is a technique where the distillate travels a short distance before being condensed. This method is highly effective for separating THC from other cannabinoids and terpenes, producing a high-purity end product. It is commonly used for creating THC-free CBD oils.

Fractional Distillation:

Fractional distillation is a more complex method that separates compounds based on their boiling points. By using a series of distillation columns, fractional distillation can achieve higher levels of purity, making it ideal for producing cannabinoid isolates. This technique is particularly useful for manufacturers who require THC removal to meet stringent regulatory requirements.

Adsorption: Targeted THC Removal

Adsorption is a process where specific compounds adhere to the surface of a solid material, known as an adsorbent. This method is highly effective for selectively removing THC from cannabis extracts without affecting other cannabinoids. Common adsorbents used in the cannabis industry include activated carbon and silica gel.

Activated Carbon:

Activated carbon is a highly porous material that can adsorb a wide range of organic compounds. It is particularly effective for removing THC from liquid extracts, making it a popular choice for producing THC-free tinctures and oils.

Silica Gel:

Silica gel is another adsorbent that can be used to remove THC from cannabis extracts. It works by selectively adsorbing THC molecules while allowing other cannabinoids to pass through. Silica gel columns are often used in combination with chromatography techniques to achieve high levels of purity.

Advanced Extraction Techniques

In addition to traditional methods, advanced extraction techniques are being developed to improve the efficiency and selectivity of THC removal. These techniques often combine multiple methods to achieve the desired level of purity and compliance.

Molecular Distillation:

Molecular distillation is an advanced form of short path distillation that operates under ultra-low pressure, allowing for the separation of compounds at lower temperatures. This technique is highly effective for producing THC-free extracts with minimal thermal degradation of cannabinoids.

Centrifugal Partition Chromatography (CPC):

CPC is a liquid-liquid chromatography technique that uses a rotating column to create a centrifugal force, enhancing the separation of compounds. This method is particularly effective for large-scale THC removal operations, providing high throughput and scalability.

Ensuring Compliance and Quality Control

While the equipment used to remove THC is crucial, ensuring compliance and maintaining product quality requires rigorous testing and quality control measures. Analytical testing is essential to verify the effectiveness of THC removal processes and ensure that the final product meets regulatory standards.

Analytical Testing:

Techniques such as gas chromatography (GC) and HPLC are used to quantify the levels of THC and other cannabinoids in the final product. Regular testing throughout the production process helps to identify any deviations and ensure consistent product quality.

Standard Operating Procedures (SOPs):

Implementing SOPs for THC removal processes ensures that all equipment is operated correctly and consistently. SOPs provide detailed instructions for each step of the process, reducing the risk of errors and improving overall efficiency.

Good Manufacturing Practices (GMP):

Adhering to GMP standards is essential for producing high-quality cannabis products. GMP guidelines cover all aspects of production, from raw material sourcing to final product testing, ensuring that products are safe, consistent, and compliant with regulations.

The removal of THC from cannabis extracts is a critical step in producing high-quality, compliant products. Utilizing the right equipment, such as chromatography systems, distillation apparatus, and adsorption materials, ensures effective

THC removal and maintains the integrity of other cannabinoids. As the cannabis industry continues to evolve, advancements in extraction and purification techniques will further enhance the ability to produce THC-free products. By implementing rigorous quality control measures and adhering to regulatory standards, manufacturers can meet consumer expectations and succeed in this dynamic market.

Write a comment ...