The global demand for natural compounds, essential oils, and plant-based extracts has grown significantly in recent decades. This shift is fueled by increasing consumer interest in natural remedies, sustainable solutions, and innovative manufacturing techniques. Among the many extraction technologies available today, hydrocarbon extraction equipment has become one of the most effective and widely discussed methods. Its efficiency, precision, and adaptability make it a cornerstone for industries that aim to maximize yields while preserving the integrity of sensitive compounds.

In this article, we will explore the fundamentals of hydrocarbon extraction, how the equipment works, its benefits, applications across various sectors, and the innovations shaping its future.

Understanding Hydrocarbon Extraction

Hydrocarbon extraction is the process of using hydrocarbons—commonly butane, propane, or blends of these gases—as solvents to separate valuable compounds from raw materials, most often plants. These solvents are particularly effective because they selectively target desired compounds, such as cannabinoids, terpenes, or essential oils, while minimizing unwanted materials.

The process typically involves placing plant material into a sealed chamber. A solvent is introduced under controlled pressure and temperature. As the solvent passes through, it dissolves compounds of interest. The resulting solution is collected and refined to remove residual solvent, leaving behind a concentrated extract that retains its natural characteristics.

This method has gained traction in industries where purity, potency, and consistency are critical.

What is Hydrocarbon Extraction Equipment?

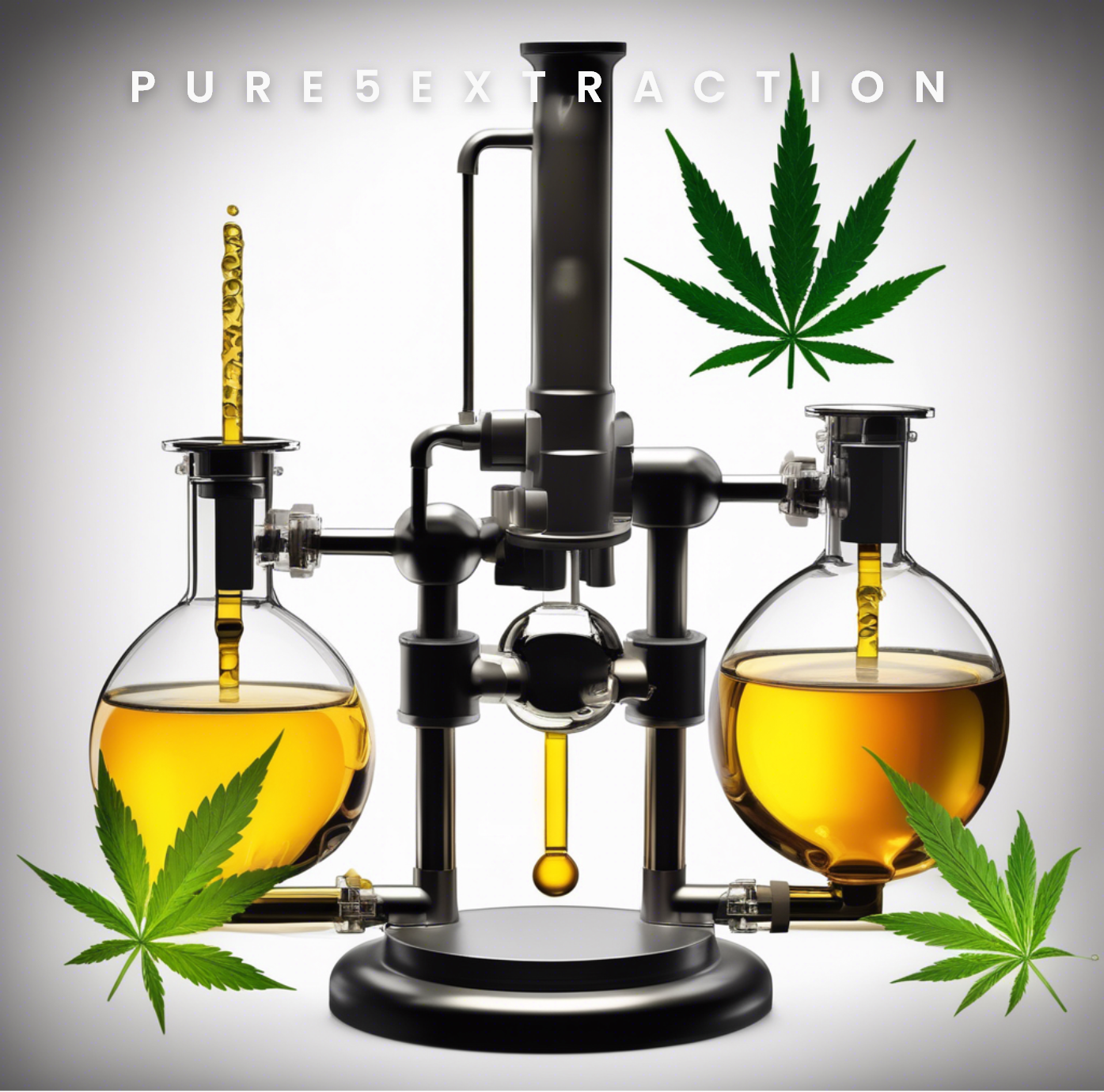

Hydrocarbon extraction equipment refers to specialized machinery designed to safely and efficiently handle hydrocarbon solvents during the extraction process. At its core, the equipment is engineered to manage pressurized gases, ensure safety protocols are met, and optimize extraction yields.

Key components often include:

Extraction Vessel – The chamber where raw material is loaded and exposed to the solvent.

Solvent Tank – A storage container holding butane, propane, or their mixtures before being introduced.

Recovery Pump – Reclaims and recycles solvents, lowering operational costs.

Collection Vessel – Captures dissolved compounds for refinement.

Filtration and Purging Systems – Remove impurities and ensure product purity.

Together, these parts form a closed-loop system that allows continuous solvent reuse, improved safety, and consistent results.

Advantages of Hydrocarbon Extraction Systems

Hydrocarbon extraction offers several benefits that explain its popularity:

High Efficiency – Solvents dissolve both volatile and non-volatile compounds, creating high-yield extracts.

Terpene Preservation – Sensitive aromatic molecules are preserved, leading to extracts with rich flavors and therapeutic qualities.

Scalability – Systems can be customized for small craft operations or scaled up for industrial facilities.

Cost-Effectiveness – Lower setup and operating expenses compared to some alternatives, without compromising quality.

Safety Considerations

The flammable nature of hydrocarbons demands strict safety measures. Modern designs and facility practices ensure risks are minimized:

Closed-Loop Systems – Prevent solvent leaks and reduce the chance of explosions.

Explosion-Proof Environments – Facilities must include proper ventilation and spark-proof systems.

Operator Training – Skilled personnel are critical for safe handling.

Compliance Standards – Regulations dictate safety benchmarks to protect workers and the environment.

By combining advanced equipment with rigorous protocols, industries can harness hydrocarbon extraction safely.

Industry Applications

Hydrocarbon-based extraction is versatile and used across multiple industries:

Botanical and Herbal Extraction – For essential oils, fragrances, and natural compounds.

Nutraceuticals – To isolate bioactive compounds that support health.

Food and Beverages – For natural flavors and concentrates.

Cosmetics and Skincare – Plant extracts are incorporated into creams, oils, and serums.

Pharmaceuticals – For high-purity compounds used in research and medicine.

Technological Innovations

As demand increases, the equipment continues to evolve. Some breakthroughs include:

Automation & Control Systems – Smart interfaces that reduce human error.

Faster Solvent Recovery – Pumps and chillers that reclaim solvents more efficiently.

Cryogenic Technology – Ultra-low temperatures to protect delicate compounds.

Enhanced Safety Features – Explosion-proof designs and real-time monitoring.

These improvements not only improve performance but also support safety and sustainability.

Environmental Responsibility

Though hydrocarbons are fossil-fuel-based, modern closed-loop systems recycle solvents to reduce waste. Industries are also exploring greener solvent alternatives and hybrid extraction methods to minimize environmental impact. By combining efficiency with sustainability, operators are able to balance production goals with environmental responsibility.

Looking to the Future

The role of hydrocarbon extraction equipment is expected to expand. Future trends include:

Hybrid extraction methods combining hydrocarbons with CO₂ or ethanol.

Development of bio-based solvents.

Stricter regulations to raise safety and environmental standards.

Custom-built equipment tailored for niche industries.

The combination of adaptability, safety, and efficiency ensures hydrocarbon extraction remains a vital tool in modern processing.

Hydrocarbon extraction has proven itself as a reliable and effective technique for obtaining high-quality plant-based extracts. With its ability to preserve delicate compounds, deliver consistent yields, and scale with industry needs, it continues to be a cornerstone for innovation.

As industries move forward, advancements in equipment design, automation, and sustainability will only enhance its importance. For those looking to combine efficiency, safety, and innovation in their operations, hydrocarbon extraction stands out as one of the most powerful solutions available.

In this journey toward innovation, one company contributing to the evolving landscape is PURE5 Extraction.

Write a comment ...